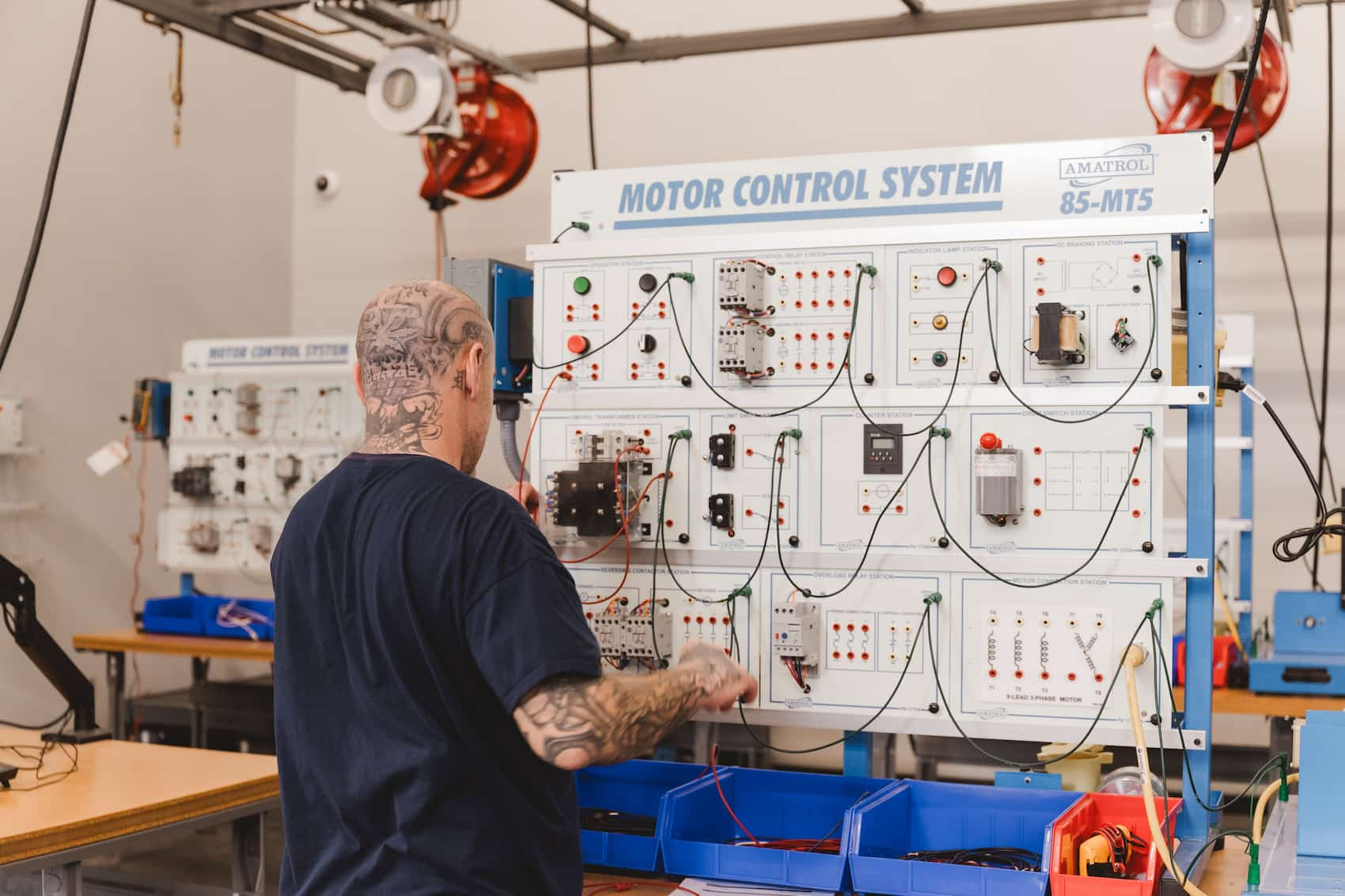

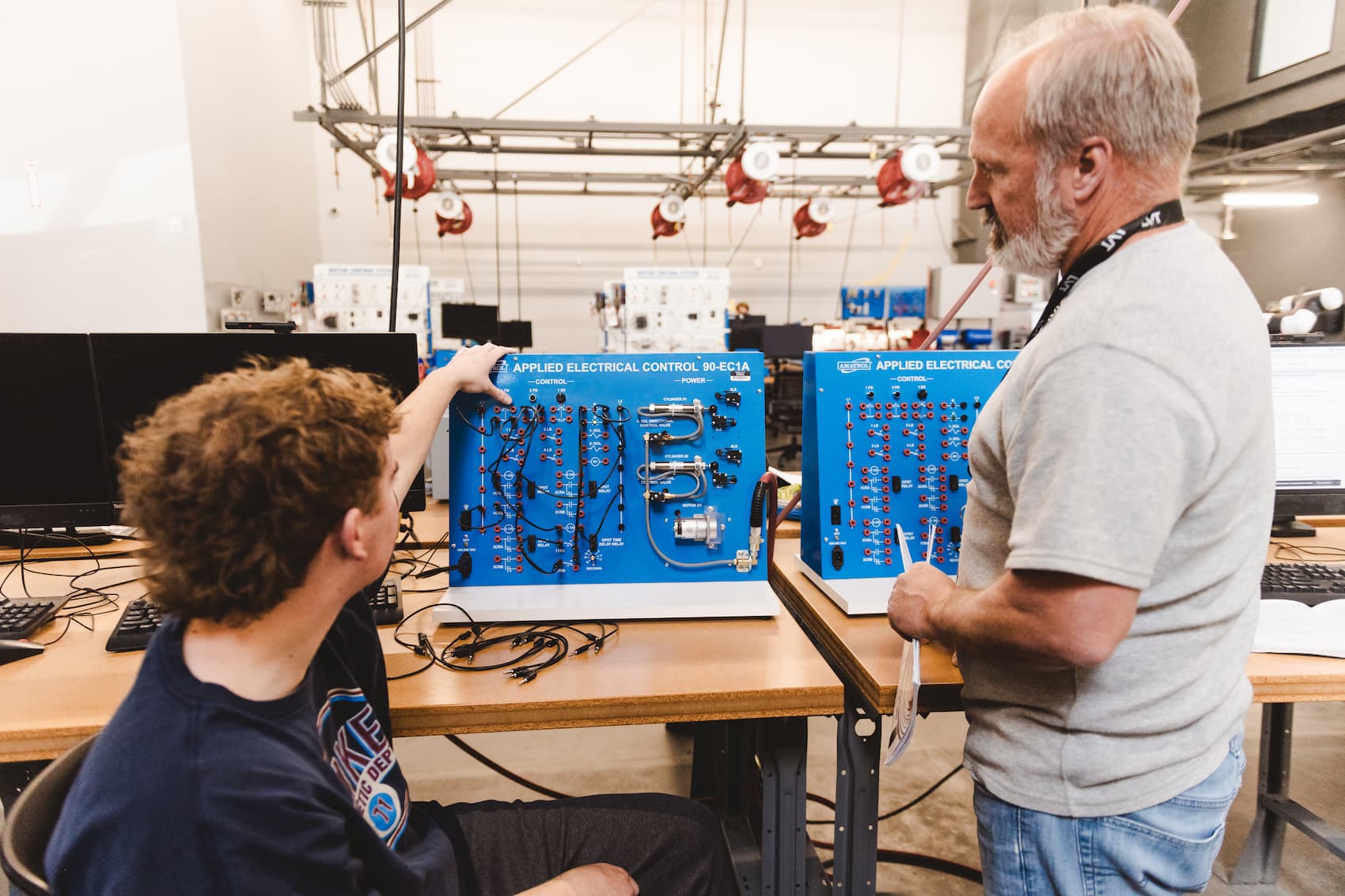

The Automation Technology program supports a wide variety of mechanical and automated systems. This program is designed to help prepare students with the necessary skills to become technicians in several critical industries. Students are introduced to a wide variety of tools, practices, and procedures. The program uses a competency based hands-on approach, with other teaching methods that are employed throughout.

This program is eligible for Financial and Veterans Aid! Learn more

Registration: This program is considered “non-term”, which means there are multiple registration dates throughout the year. Here are the registration dates with the correlating start date:

program location | Registration date | next start date |

|---|---|---|

Lehi, Orem | September 2, 2025 | September 8, 2025 |

Lehi, Orem, Payson | September 29, 2025 | October 6, 2025 |

Lehi, Orem, Payson | October 27, 2025 | November 3, 2025 |

Lehi, Orem, Payson | November 4, 2025 | December 1, 2025 |

Lehi, Orem, Payson | December 8, 2025 | January 5, 2026 |

Lehi, Orem, Payson | January 26, 2026 | February 2, 2026 |

Lehi, Orem, Payson | February 23, 2026 | March 2, 2026 |

Lehi, Orem, Payson | March 30, 2026 | April 6, 2026 |

Lehi, Orem, Payson | April 27, 2026 | May 4, 2026 |

Lehi, Orem, Payson | May 18, 2026 | June 1, 2026 |

Minimum Age Requirement: 16 years old. High school students must be in their junior or senior year.

Registration opens at 8:00 AM in Learning Stream, and remains open until classes are full.

| Term | Campus | Room # | Start Date – End Date | Time | Days |

|---|---|---|---|---|---|

| Spring 2026 | Lehi Building B | 125 | 02/02/2026 | 7:30 am – 10:30 am | Monday – Friday |

| Spring 2026 | Lehi Building B | 125 | 02/02/2026 | 11:30 am – 2:30 pm | Monday – Thursday |

| Spring 2026 | Lehi Building B | 125 | 02/02/2026 | 6:00 pm – 9:00 pm | Monday – Thursday |

| Spring 2026 | Orem Building A | 107 | 02/02/2026 | 7:30 am – 10:30 am | Monday – Fridaty |

| Spring 2026 | Orem Building A | 107 | 02/02/2026 | 11:30 am – 2:30 pm | Monday – Friday |

| Spring 2026 | Payson | – | 02/02/2026 | 7:30 am – 10:30 am | Monday -Friday |

| Spring 2026 | Payson | – | 02/02/2026 | 11:45 pm – 2:45 pm | Monday – Friday |

| Spring 2026 | Lehi Building B | 125 | 03/02/2026 | 7:30 am – 10:30 am | Monday – Friday |

| Spring 2026 | Lehi Building B | 125 | 03/02/2026 | 11:30 am – 2:30 pm | Monday – Friday |

| Spring 2026 | Lehi Building B | 125 | 03/02/2026 | 6:00 pm – 9:00 pm | Monday – Thursday |

| Spring 2026 | Orem Building A | 107 | 03/02/2026 | 7:30 am – 10:30 am | Monday – Friday |

| Spring 2026 | Orem Building A | 107 | 03/02/2026 | 11:30 am – 2:3 pm | Monday-Fridy |

| Spring 2026 | Payson | – | 03/02/2026 | 7:30 am – 10:30 am | Monday – Friday |

| Spring 2026 | Payson | – | 03/02/2026 | 11:45 pm – 2:45 pm | Monday – Friday |

| Spring 2026 | Lehi Building B | 125 | 04/13/2026 | 7:30 am – 10:30 am | Monday – Friday |

| Spring 2026 | Lehi Building B | 125 | 04/13/2026 | 11:30 am – 2:30 pm | Monday – Friday |

| Spring 2026 | Lehi Building B | 125 | 04/13/2026 | 6:00 pm- 9:00 pm | Monday – Thursday |

| Spring 2026 | Orem Building A | 107 | 04/13/2026 | 7:30 am – 10;30 am | Monday – Friday |

| Spring 2026 | Orem Building A | 107 | 04/13/2026 | 11:30 am – 2:30 pm | Monday – Friday |

| Spring 2026 | Payson | – | 04/13/2026 | 7:30 am – 10:30 pm | Monday – Friday |

| Spring 2026 | Payson | – | 04/13/2026 | 11:45 pm – 2:45 pm | Monday – Friday |

| Spring 2026 | Lehi Building B | 125 | 05/0/2026 | 6:00 pm – 9:00 pm | Monday – Thursday |

| Spring 2026 | Lehi Building B | 125 | 05/04/2026 | 7:30 am – 10:30 am | Monday – Friday |

| Spring 2026 | Lehi Building B | 125 | 05/04/2026 | 11:30 am – 2:30 pm | Monday – Friay |

| Spring 2026 | Orem Building A | 107 | 05/04/2026 | 7:30 am – 10:30 am | Monday – Friday |

| Term | Campus | Room # | Start Date – End Date | Time | Days |

|---|---|---|---|---|---|

| Summer 2026 | Lehi Building B | 125 | non-term | 7:30 am – 10:30 am | M-TH (Hybrid Friday) |

| Summer 2026 | Lehi Building B | 125 | non-term | 11:30 am – 2:30 pm | M-TH (Hybrid Friday) |

| Summer 2026 | Lehi Building B | 125 | non-term | 6:00 pm- 9:00 pm | M-TH (Hybrid Friday) |

| Fall 2026 | Lehi Building B | 125 | non-term | 7:30 am – 10:30 am | M-TH (Hybrid Friday) |

| Fall 2026 | Lehi Building B | 125 | non-term | 11:30 am – 2:30 pm | M-TH (Hybrid Friday) |

| Fall 2026 | Lehi Building B | 125 | non-term | 6:00 pm – 9:00 pm | M-TH (Hybrid Friday) |

| Spring 2027 | Lehi Building B | 125 | non-term | 7:30 am – 10:30 am | M-TH (Hybrid Friday) |

| Spring 2027 | Lehi Building B | 125 | non-term | 11:30 am – 2:30 pm | M-TH (Hybrid Friday) |

| Spring 2027 | Lehi Building B | 125 | non-term | 6:00 pm – 9:00 pmn | M-TH (Hybrid Friday) |

| Summer 2027 | Lehi Building B | 125 | non-term | 7:30 am – 10:30 am | M-TH (Hybrid Friday) |

| Summer 2027 | Lehi Building B | 125 | non-term | 11:30 am – 2:30 pm | M-TH (Hybrid Friday) |

| Summer 2027 | Lehi Building B | 125 | non-term | 6:00 pm – 9:00 pm | M-TH (Hybrid Friday) |

| Summer 2026 | Orem Building A | 107 | non-term | 7:30 am – 10:30 am | M-TH (Hybrid Friday) |

| Summer 2026 | Orem Building A | 107 | non-term | 11:30 am – 2:30 pm | M-TH (Hybrid Friday) |

| Fall 2026 | Orem Building A | 107 | non-term | 7:30 am – 10:30 am | M-TH (Hybrid Friday) |

| Fall 2026 | Orem Building A | 107 | non-term | 11:30 am – 2:30 pm | M-TH (Hybrid Friday) |

| Spring 2027 | Orem Building A | 107 | non-term | 7:30 am – 10:30 am | M-TH (Hybrid Friday) |

| Spring 2027 | Orem Building A | 107 | non-term | 11:30 am – 2:30 pm | M-TH (Hybrid Friday) |

| Summer 2027 | Orem Building A | 107 | non-term | 7:30 am – 10:30 am | M-TH (Hybrid Friday) |

| Summer 2027 | Orem Building A | 107 | non-term | 11:30 am – 2:30 pm | M-TH (Hybrid Friday) |

| Summer 2026 | Payson | 111 | non-term | 7:30 am – 10:30 am | M-TH (Hybrid Friday) |

| Summer 2026 | Payson | 111 | non-term | 11:45 pm – 2:45 pm | M-TH (Hybrid Friday) |

| Fall 2026 | Payson | 111 | non-term | 7:30 am – 10:30 am | M-TH (Hybrid Friday) |

| Fall 2026 | Payson | 111 | non-term | 11:45 pm – 2:45 pm | M-TH (Hybrid Friday) |

| Spring 2027 | Payson | 111 | non-term | 7:30 am – 10:30 am | M-TH (Hybrid Friday) |

Total hours: 930

Required Courses

| Course Name | Course Hours | Course Credits | Tuition | Course Fees |

|---|---|---|---|---|

| Essential Skills and Safety | 90 | 3 | $360.00 | $40.00 |

| Pneumatics | 60 | 2 | $240.00 | $65.00 |

| Hydraulics | 60 | 2 | $240.00 | $64.00 |

| Industrial Mechanics | 90 | 3 | $360.00 | $61.00 |

| Electrical Systems | 60 | 2 | $240.00 | $44.00 |

| Motor Controls | 90 | 3 | $360.00 | $91.00 |

| Programmable Logic Controllers | 120 | 4 | $480.00 | $68.00 |

| Applied System Diagnostics | 60 | 2 | $240.00 | $34.00 |

Optional Courses

| Course Name | Course Hours | Course Credits | Tuition | Course Fees |

|---|---|---|---|---|

| Rotating Machines | 60 | 2 | $240.00 | $34.00 |

| Robotics I | 30 | 1 | $120.00 | $44.00 |

| FANUC Robot | 30 | 1 | $120.00 | $134.00 |

| Programmable Logic Controllers II | 90 | 3 | $360.00 | $51.00 |

| Electro-Fluid Power | 30 | 1 | $120.00 | $17.00 |

Upon registration, you will register and submit payment for the first course in the program.

While not required, you may make a deposit, in person or online, for the full program upon registration to be held in your student account.

For start dates before July 1, 2026

| Tuition/Fees | Cost |

|---|---|

| Tuition: | $3,720.00 |

| Registration Fee: | $40.00 |

| Application Fee: | $0.00 |

| Course Fees: | $834.00 |

| Required Materials: | $0.00 |

| Total Cost of Program: | $4,717 |

For start dates after July 1, 2026

| Tuition/Fees | Cost |

|---|---|

| Tuition: | $3,600.00 |

| Registration Fee: | $0.00 |

| Application Fee: | $0.00 |

| Course Fees: | $552.00 |

| Required Materials: | $0.00 |

| Total Cost of Program: | $4,156 |

Note: High school students attend MTECH tuition free, and are only responsible for fees and materials.

Course-by-course cost breakdowns can be found on the “Courses” tab above.

Upon registration, you will register and submit payment for the first course in the program.

While not required, you may make a deposit, in person or online, for the full program upon registration to be held in your student account.

For start dates before July 1, 2026

Materials | Notes | Costs | |

|---|---|---|---|

Safety Glasses | Available in the MTECH Store | $4.00 | |

SACA Annual Subscription | ($7/applicable course) | Included in fees within each course | |

AMATROL E-Learning Annual Subscription | ( $17/course) | Included in fees within each course |

Exam Name | Additional Information | Cost | ||

|---|---|---|---|---|

Fanuc HandlingTool Operation and Programing | Included in fees | |||

Fanuc Certified Robot Operator (NOCTI) | $30 | |||

C-101 Certified Industry 4.0 Associate 1 – Basic Operations | SACA Certification | Included in fees | ||

C-103 Associate-Robot Systems Certification | SACA Certification | Included in fees | ||

C-201 Electrical Systems 1 | SACA Certification | Included in fees | ||

C-202 Motor Control Systems 1 | SACA Certification | Included in fees | ||

C-203 Variable Frequency Drive Systems 1 | SACA Certification | Included in fees | ||

C-206 Electrical System Installation 1 | SACA Certification | Included in fees | ||

C-207 Programmable Controller Systems 1 | SACA Certification | Included in fees | ||

C-208 Programmable Controller Troubleshooting 1 | SACA Certification | Included in fees | ||

C-209 Pneumatic Systems 1 | SACA Certification | Included in fees | ||

C-210 Mechanical Power Systems 1 | SACA Certification | Included in fees | ||

C-215 Robot Systems Operations 1 | SACA Certification | Included in fees | ||

C-255 Hydraulic Systems 1 | SACA Certification | Included in fees |

For start dates after July 1, 2026

Materials | Notes | Costs | |

|---|---|---|---|

Safety Glasses | Available in the MTECH Store | $4.00 | |

SACA Subscription | ($7/applicable course) | Included in fees within each course | |

AMATROL E-Learning Subscription | ( $11/credit) | Included in fees within each course | |

Use of own personal computing device (Laptop Computer w/ Minimum system requirements) | Operating System: Windows 11 Processor: Intel Core 2 Duo @ 2.8 GHz RAM: 4 GB Hard Disk Space: 16 GB free Graphics: DirectX 9 with WDDM 1.0 or higher driver Recommended system requirements Processor: Intel Core i5 @ 2.4 GHz RAM: 8 GB Hard Disk Space: 20 GB free Graphics: DirectX 9 with WDDM 1.0 or higher driver | Varies – Students are responsible for purchasing their own laptop. |

Exam Name | Additional Information | Cost | ||

|---|---|---|---|---|

C-101 Certified Industry 4.0 Associate 1 – Basic Operations | SACA Certification | Included in fees | ||

C-201 Electrical Systems 1 | SACA Certification | Included in fees | ||

C-202 Motor Control Systems 1 | SACA Certification | Included in fees | ||

C-203 Variable Frequency Drive Systems 1 | SACA Certification | Included in fees | ||

C-204 Motor Control Troubleshooting Systems 1 | SACA Certification | Included in fees | ||

C-206 Electrical System Installation 1 | SACA Certification | Included in fees | ||

C-207 Programmable Controller Systems 1 | SACA Certification | Included in fees | ||

C-208 Programmable Controller Troubleshooting 1 | SACA Certification | Included in fees | ||

C-209 Pneumatic Systems 1 | SACA Certification | Included in fees | ||

C-210 Mechanical Power Systems 1 | SACA Certification | Included in fees | ||

C-215 Robot Systems Operations 1 | SACA Certification | Included in fees | ||

C-255 Hydraulic Systems 1 | SACA Certification | Included in fees | ||

C-307 Electronic Systems Installation 1 | SACA Certification | Included in fees | ||

C-309 Programmable Controller Systems 2 | SACA Certification | Included in fees |

For start dates before July 1, 2026

MTECH Program Certificate in Automation Technology

SACA Certifications

C-101 Certified Industry 4.0 Associate 1 – Basic Operations

C-103 Associate-Robot Systems Certification

C-201 Electrical Systems 1

C-202 Motor Control Systems 1

C-203 Variable Frequency Drive Systems 1

C-206 Electrical System Installation 1

C-207 Programmable

Controller Systems 1

C-208 Programmable Controller Troubleshooting 1

C-209 Pneumatic Systems 1

C-210 Mechanical Power Systems 1

C-215 Robot Systems Operations 1

C-255 Hydraulic Systems 1

Fanuc Handling Tool Operation and Programming

Fanuc Certified Robot Operator (NOCTI)

For start dates after July 1, 2026

MTECH Program Certificate in Automation Technology

SACA Certifications

C-101 Certified Industry 4.0 Associate 1- Basic Operations

C-201 Electrical Systems 1

C-202 Motor Control Systems 1

C-203 Variable Frequency Drive Systems 1

C-204 Motor Control Troubleshooting Systems 1

C-206 Electrical System Installation 1

C-207 C-210 Mechanical Power Systems 1

C-208 Programmable Controller Troubleshooting 1

C-209 Pneumatics Systems 1

C-210 Mechanical Power Systems 1

C-215 Robot Systems Operations 1

C-255 Hydraulic Systems 1

C-307 Electronic Systems Installation 1

C-309 Programmable Controller Systems 2

What kind of jobs are available?

Automation Technology prepares you to be an equipment technician. Equipment Technicians troubleshoot and problem-solve all of the components involved in automated manufacturing.

How and where are the things I learn in this class used?

Automated processes (manufacturing line, automated assembly line) are used in almost everything. The primary businesses in Utah using these technologies are food production, packaging, and microchip manufacturings.

Do we get to see any of these machines working?

We schedule tours with industry leaders several times per year. Students will see many of the concepts and components in-action as they particpate in tours at various manufacturing facilities.

Admission requirements may be met by taking the Entrance Assessment OR by providing qualifying documentation. The Entrance Assessment can be taken at a Testing Center, and qualifying documents can be sent to transcripts@mtec.edu.

Learn more about the assessment HERE

Appointments can be scheduled HERE.

Once previous steps have been completed, eligibility is met to register for the first course within the program. Registration is on a first-come, first-serve basis. Tuition and fees are due for the first course upon registration.

Prospective students can register through Learning Stream or in person at Student Services.

To register, you will use your Canvas login and password and will need your MTECH Student ID number. These items are provided in the email you received after your MTECH application; however, if you cannot find this information, please connect with our Student Services team prior to registration day.

Please be sure you have verified your Canvas email address before registering.

After a course is in your cart, you will have 5 minutes to complete the checkout process before it is unreserved and may be taken by another student.

jeffrey.erickson@mtec.edu

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |